Description

Main Technical Parameters

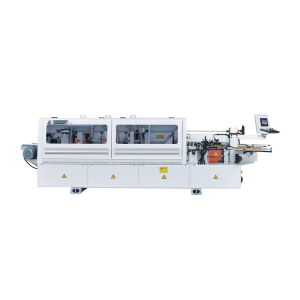

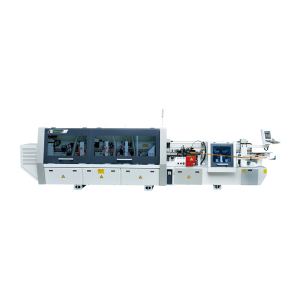

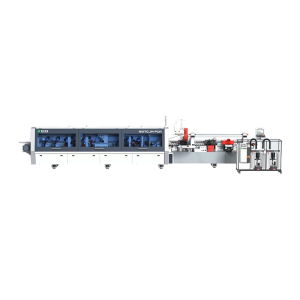

Model: NBF7PCG-PUR

- Workpiece Length: ≥120mm, ≥200mm with tracking

- Dust Extraction Ports: φ125mm×9

- Workpiece Width: ≥80mm

- Total Power: 30kW

- Workpiece Thickness:

- Standard Panels: 9-60mm

- Aluminum Honeycomb Panels: 9-22mm

- Net Weight: 6110kg

- Edge Band Thickness:

- Standard Panels: 0.4-3mm

- Aluminum Honeycomb Panels: 1-2mm

- Equipment Dimensions (Standalone): 11200×1050×1850mm

- Feeding Speed:

- Standard Panels: 12/16/20m/min

- Aluminum Honeycomb Panels: 12/16m/min

EQUIPMENT HIGHLIGHT

- Seamless edge sealing, zero glue lines, more perfect appearance

- The unique rubber door structure adopts the split-flow squeegee principle, with no sawdust clogging the rubber shaft, no stroke limit, and uniform and stable glue distribution

- The upper end cover is integrally processed from ductile iron with high precision and multi-channel sealing design to ensure no glue leakage when used under high temperatures.

- Can control the rapid switching of two kinds of PUR glue to improve processing efficiency; intelligent control touch screen, simple and convenient operation

- The heavy-duty one-piece steel frame is made of robot welding, natural aging, annealing, shot peening, and one-time molding in a gantry machining center to ensure the stability of the machine body

- Crawler pressing material, the way the crawler track contacts the surface of the plate, the pressing plate processing is more stable, and the workpiece runs smoothly

- Dual-channel servo belt feeding can meet the needs of rapid switching between two types of plates

- Double guide rails quickly align to ensure perfect front and rear alignment under high-speed edge sealing

- Four-knife profiling tracking can ensure both quality and efficiency

- 2 sets of horizontal scraping wheels, both with avoidance, strong suction power and easy adjustment;

- Reciprocating polishing avoids fixing the same position of the polishing wheel and can better ensure the polishing effect

- Green energy-saving function: When the machine does not process panels for a certain period of time (value can be set), the machine automatically enters standby mode

- The integrated encoder replaces the traditional limit switch, reducing failures caused by the mechanical life of the limit switch itself and effectively improving machine stability.

- The equipment is equipped with a honeycomb panel pressing system. PUR glue suitable for aluminum honeycomb panels is selected for edge sealing, which increases the pressing stroke and curing time of the honeycomb panel and reduces the need for wood and sealing. Sideband impact.

There are no reviews yet.